These days, the world of manufacturing is standing on the precipice of a technological revolution, which is enabled by state-of-the-art technology, fiber laser cutting.

In fact, traditional manufacturing methods have long yielded high-precision and efficient technology, which has finally been fulfilled with fiber lasers.

Let’s check out what fiber laser cutting is and what its key benefits are.

What is fiber laser cutting?

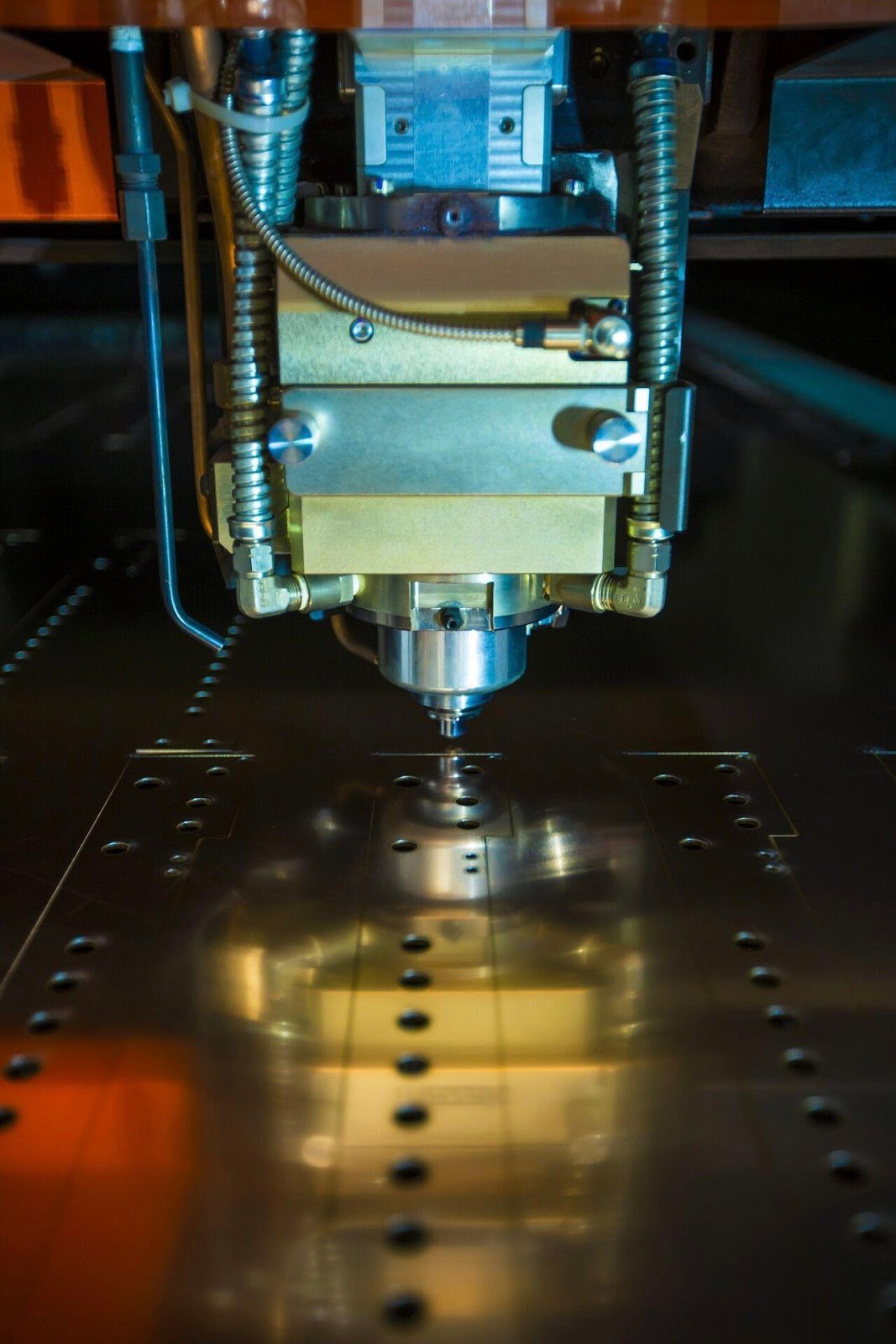

Fiber laser cutting is a technique employing a laser beam generated by fiber optics to precisely cut through materials.

Its breakthrough is a result not only of its ability to provide cleaner, more precise cuts than traditional cutting methods but also of the array of materials it can cut, such as:

- steel,

- aluminum,

- copper,

- brass,

- alloy.

Moreover, fiber lasers entail advanced modern solutions, such as automation, or continuous process control systems.

In the process of laser cutting, the energy of the laser beam melts the material within the kerf, while the molten metal is blown away by the gas. Consequently, if there is sufficient laser output power, such technology can melt and cut any copper or aluminum sheet.

It is also worth mentioning that the design of the fiber laser allows the cutting of various complex geometries with high quality along the edges.

What are the key benefits of fiber laser cutting?

High precision

First of all, fiber laser cutting guarantees high-quality cuts, even the most complex ones. Fiber lasers come with fine-tuned control, which allows for unprecedented accuracy in the manufacturing process.

Unlike traditional cutting methods, which have difficulty achieving intricate designs without sacrificing material integrity, fiber laser cutting technology enables the creation of complex designs with a high degree of precision. As a result, it leads to enhanced product quality and a reduced need for additional processing or finishing.

Efficiency

Efficiency is another key advantage of fiber lasers. Since the cutting process is automated and monitored by advanced software, the risk of human errors is reduced to a minimum, and the duration is shorter.

Apart from this, fiber lasers require less power than other cutting methods and have longer lifespans, leading to lower maintenance costs over time. As a result, fiber laser cutting results in reduced operational costs and increased productivity, which is a win-win for any business.

Flexibility

Another pillar of the fiber laser cutting revolution is its flexibility. Traditional cutting methods are very often restrictive, limiting the types of materials that can be worked on and the complexity of the designs.

Fiber laser machines, though, can handle a wide variety of materials with different thicknesses and hardness levels.

All in all, fiber laser cutting technology is not just the latest trend, but a game-changer in the manufacturing industry. By offering high precision, efficiency, and flexibility, it is revolutionizing the industry’s operational processes and product output.

Interesting Related Article: “What are the Applications of Laser in Industry?“

from Latest Technology News https://ift.tt/ERq7QL2

via IFTTT

0 Comments