In the fast-paced world of electronics, the technology behind semiconductor packaging is constantly evolving to meet the demands for smaller, more efficient, and higher-performing devices. One of the innovative solutions that has gained significant traction is the flip-chip package substrate. In this article, we’ll delve into the details of flip-chip package substrates, their advantages, applications, and why they matter in modern electronics.

1. Introduction to Flip-Chip Package Substrate

Understanding Semiconductor Packaging

Semiconductor packaging is a crucial stage in the electronics manufacturing process. It involves enclosing the delicate semiconductor chip within a protective casing to ensure its functionality, reliability, and integration into various devices. Over the years, different packaging techniques have emerged to cater to different needs, and flip-chip technology is a standout.

Evolution of Flip-Chip Technology

Flip-chip technology, first introduced decades ago, has undergone significant transformations. Initially used for its space-saving advantages, it has evolved to offer a wide array of benefits beyond miniaturization. Flip-chip package substrates, a key component of this technology, have revolutionized the way semiconductor devices are packaged and interconnected.

2. What is a Flip-Chip Package Substrate?

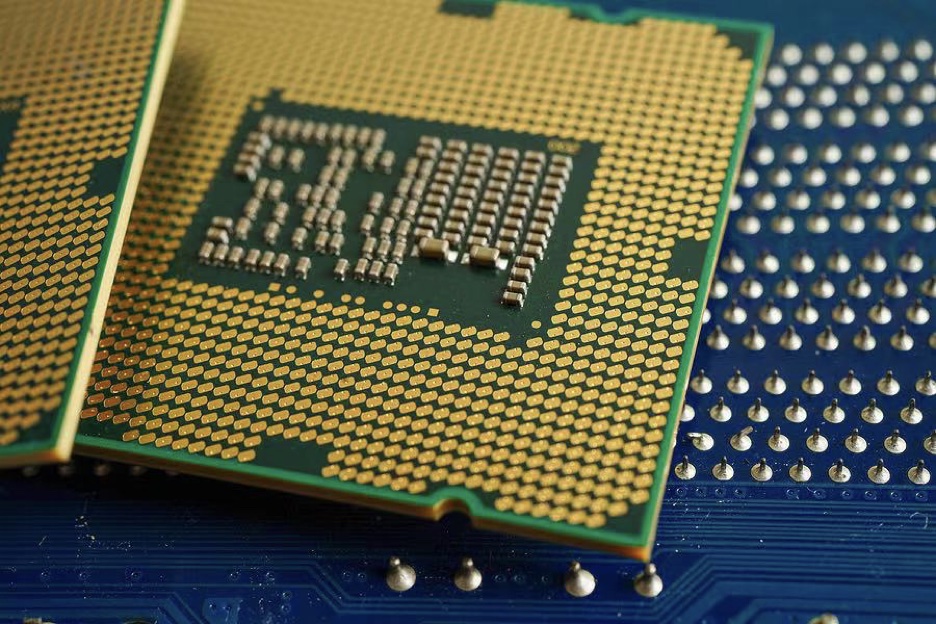

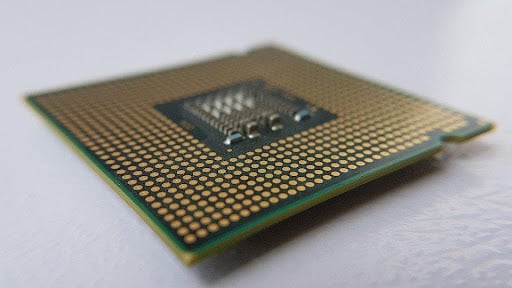

Flip-Chip Assembly Process

The flip-chip assembly process involves the direct attachment of the semiconductor chip to the substrate, creating a compact and efficient connection. Unlike traditional wire bonding methods, where the connections are made on the chip’s periphery, flip-chip technology enables connections directly on the chip’s active surface.

Importance of Substrate Materials

The substrate material used in flip-chip packaging plays a pivotal role. It provides structural support, electrical connections, and thermal pathways. Materials like silicon, organic substrates, and ceramics are commonly employed due to their excellent electrical and thermal properties.

3. Advantages of Flip-Chip Package Substrates

Enhanced Thermal Performance

Flip-chip package substrates offer superior thermal dissipation compared to conventional packaging methods. Direct attachment of the chip to the substrate allows for efficient heat transfer, which is crucial in preventing overheating and maintaining optimal chip performance.

Miniaturization and Higher Density

With the connections established on the chip’s active surface, the need for bond wires or interconnects is eliminated. This results in a significant reduction in the overall size of the packaged device, enabling the creation of smaller and more compact electronic products.

Improved Electrical and Thermal Performance

The shorter interconnection lengths in flip-chip packaging lead to reduced signal delays and enhanced electrical performance. Additionally, the efficient heat dissipation contributes to improved thermal stability, ensuring the semiconductor operates within safe temperature limits.

4. Applications Across Industries

Consumer Electronics

Flip-chip technology has revolutionized consumer electronics by enabling the production of thinner smartphones, tablets, and wearables. The compact design and enhanced performance of flip-chip package substrates contribute to the sleek and powerful devices we use in our daily lives.

Automotive Sector

In the automotive industry, where reliability and durability are paramount, flip-chip package substrates find applications in engine control units, infotainment systems, and safety modules. The technology’s ability to withstand harsh environments and vibrations makes it a preferred choice.

Medical Devices

Medical devices benefit from the miniaturization and high-performance capabilities of flip-chip package substrates. From implantable devices to diagnostic equipment, these substrates contribute to the development of cutting-edge medical technology.

If you’re looking for a Flip-Chip Package Substrate manufacturer. You can check out a Package Substrate manufacturer

5. Key Considerations in Design and Manufacturing

Substrate Material Selection

The choice of substrate material depends on various factors, including thermal requirements, electrical properties, and cost considerations. Designers must carefully select the appropriate material to ensure optimal performance and reliability.

Thermal Management Techniques

Efficient thermal management is crucial for the longevity of semiconductor devices. Techniques such as incorporating heat sinks, thermal vias, and advanced cooling solutions play a vital role in maintaining optimal operating temperatures.

6. Challenges and Future Trends

Reliability Concerns

While flip-chip package substrates offer numerous advantages, concerns regarding mechanical stress and long-term reliability still exist. Ongoing research and innovative design approaches aim to address these challenges and enhance the robustness of flip-chip packaging.

Integration with Advanced Technologies

As technology continues to evolve, flip-chip package substrates are being integrated with advanced technologies like 5G, AI, and IoT. These substrates are pivotal in enabling the seamless operation of these technologies by providing high-speed connectivity and efficient data processing.

7. Importance of Flip-Chip Substrates in Modern Electronics

Enabling Wearable Technology

The rise of wearable technology, including smartwatches and fitness trackers, is made possible by the compact size and performance capabilities of flip-chip package substrates. These substrates allow manufacturers to create feature-rich wearables that are comfortable and unobtrusive.

Powering 5G Infrastructure

The rollout of 5G networks demands high-performance semiconductor devices that can handle increased data processing. Flip-chip package substrates play a crucial role in meeting these demands by providing the necessary speed, efficiency, and thermal management for 5G infrastructure.

8. Conclusion

In the ever-evolving landscape of electronics, flip-chip package substrates stand as a testament to innovation in semiconductor packaging. Their ability to enhance thermal performance, enable miniaturization, and support advanced technologies makes them indispensable in modern electronics.

As we continue to push the boundaries of what’s possible, flip-chip technology and its associated substrates will likely play an increasingly vital role in shaping the future of electronics.

Interesting Related Article: “Types of RFID Chip You Need to Know: Exploring the World of RFID Technology“

from Latest Technology News https://ift.tt/WO54jte

via IFTTT

0 Comments